Szerszámgép alapöntvények

a termékek származási helye Donggang, Dandong, Liaoning tartomány

szállítási kapacitás 10000 tonna/év

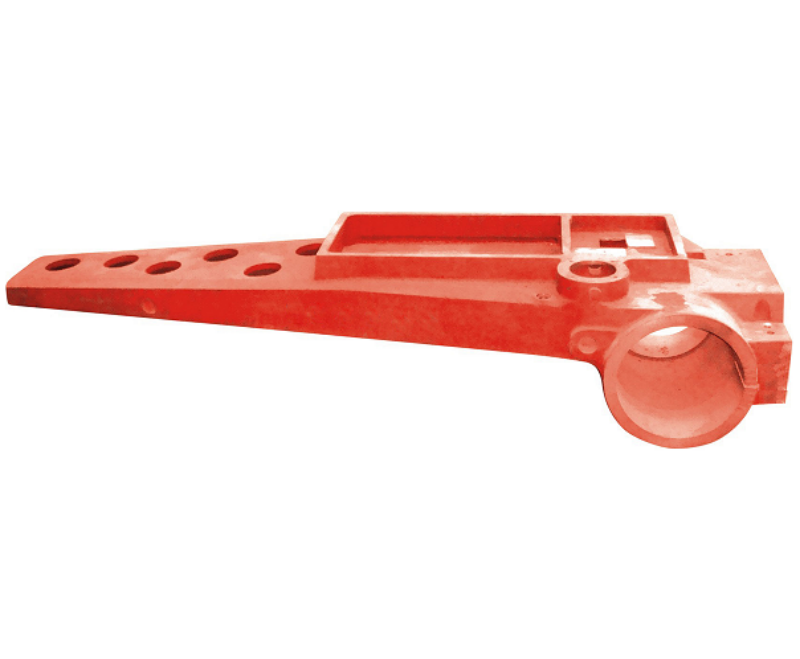

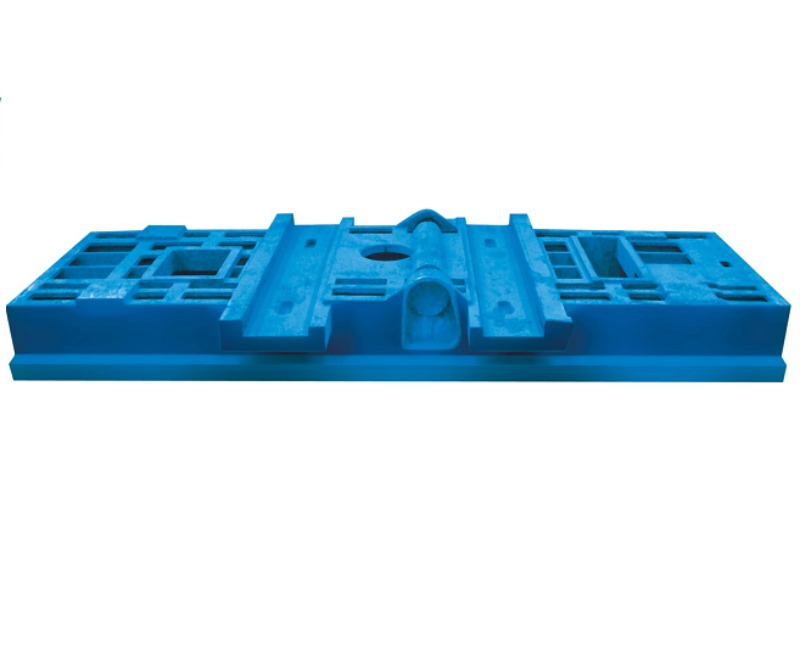

1. A szerszámgép alapöntésének szerkezete stabil, az integrált öntés öntési módszerét alkalmazza, amely stabil támogatást és rögzítést biztosíthat a szerszámgép munkarészeihez.

2. A gépágy alapja ütésálló, amely hatékonyan elnyeli és csillapítja a szerszámgép által működés közben keltett vibrációt és ütést.

3. A nagy öntöttvas eszterga alapöntvények feldolgozási pontossága garantált, és az alapöntvények precíziós öntési és hőkezelési eljárásokon estek át a méretpontosság és a geometriai alakpontosság biztosítása érdekében.

Introduction to Machine Tool Base Castings:

Machine tool base casting is an important part of the machine tool and also the supporting structure of the machine tool. Machine tool casting kits are primarily used to carry the weight and moment of each part of the machine tool to ensure the stability and accuracy of the machine tool. Machine tool casting kits are made of cast iron, and the cast iron parts of the machine tool base have various structural forms, generally including the base body and the bottom surface of the base. The Machine bed base of the base usually adopts a box-type, bed-type or shell-type structure, which has sufficient strength and rigidity, and can withstand various moments and vibrations during the operation of the machine tool. The bottom surface of the base is used to contact the ground, and usually has enough flatness and stability to ensure the smooth operation of the machine tool. Has good rigidity and wear resistance. The design and manufacture of the machine bed base need to consider the use requirements of the machine tool and the working environment conditions. In the design process, it is necessary to reasonably arrange the structural layout and support methods of the base to improve the rigidity and stability of the base. During the manufacturing process, it is necessary to strictly control the material and process of the castings to ensure the quality and precision of large Cast Iron Lathe Base Castings.Machine Tool Base Castings are Machine bed base.

Advantages of Machine Tool Base Castings:

1. Machine tool base casting can provide a stable support for the bed of the machine tool, ensuring the stability and working accuracy of the machine tool.

2. Machine bed base can be designed into different shapes and structures according to the type and path of the machine tool, which can meet the different needs of different machine tools.

3. Large Cast Iron Lathe Base Castings adopt precise processing and assembly technology to ensure the flatness, verticality and levelness of the base, and ensure the positioning accuracy and working reliability of the machine tool.

4. The manufacturing cost of Machine tool casting kits is low, and a complete base structure can be obtained through one-time casting, which reduces the processing, assembly and debugging of parts and components, and reduces the manufacturing cost.

5.As a type of machine tool casting kits, machine bed base is sturdy and durable. Machine tool casting kits contain a variety of castings, including Machine bed base, Large Cast Iron Lathe Base Castings, etc.Among them, Machine bed base is the foundation.

The scope of application of Machine Tool Base Castings includes the following aspects:

1. Metal processing machine tools: including milling machines, lathes, drilling machines, grinding machines, etc. Machine tool base casting can provide a stable support structure to ensure the accuracy and stability of the machine tool.

2. Plastic processing machine tools: such as injection molding machines, extruders, etc. Machine bed base can provide a stable support structure to ensure the stability of the machine tool at high speed.

3. Woodworking machine tools: such as woodworking planers, woodworking engraving machines, etc. Large Cast Iron Lathe Base Castings can provide a stable support structure to ensure the accuracy and stability of the machine tool.

4. Stone processing machine tools: such as stone cutting machines, stone engraving machines, etc. Machine tool casting kits can provide a stable support structure to ensure the stability of the machine tool during high-load work.

F:Are you a trading company or manufacturer?

Q:We are factory.

F:How will you control the quality?

A:We have quality control department, which will set up control plan before stating the project.

F:How can I place order?

A:You can contact us by email about your order details, or place order on line.